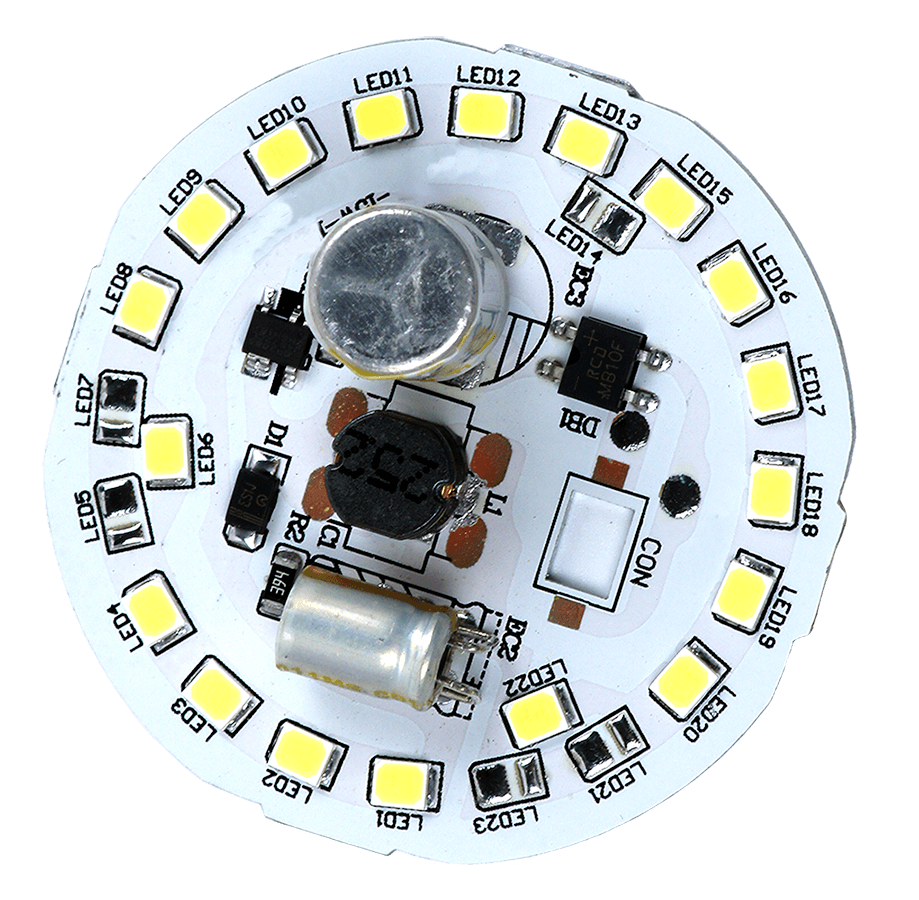

Although the LED industry has grown fast in recent years, the issue of heat dissipation has confounded LED application and growth, particularly in the sector of lighting. The use of Metal Core PCB opens up a new way to effectively solve LED heat dissipation.

What is Metal Core PCB?

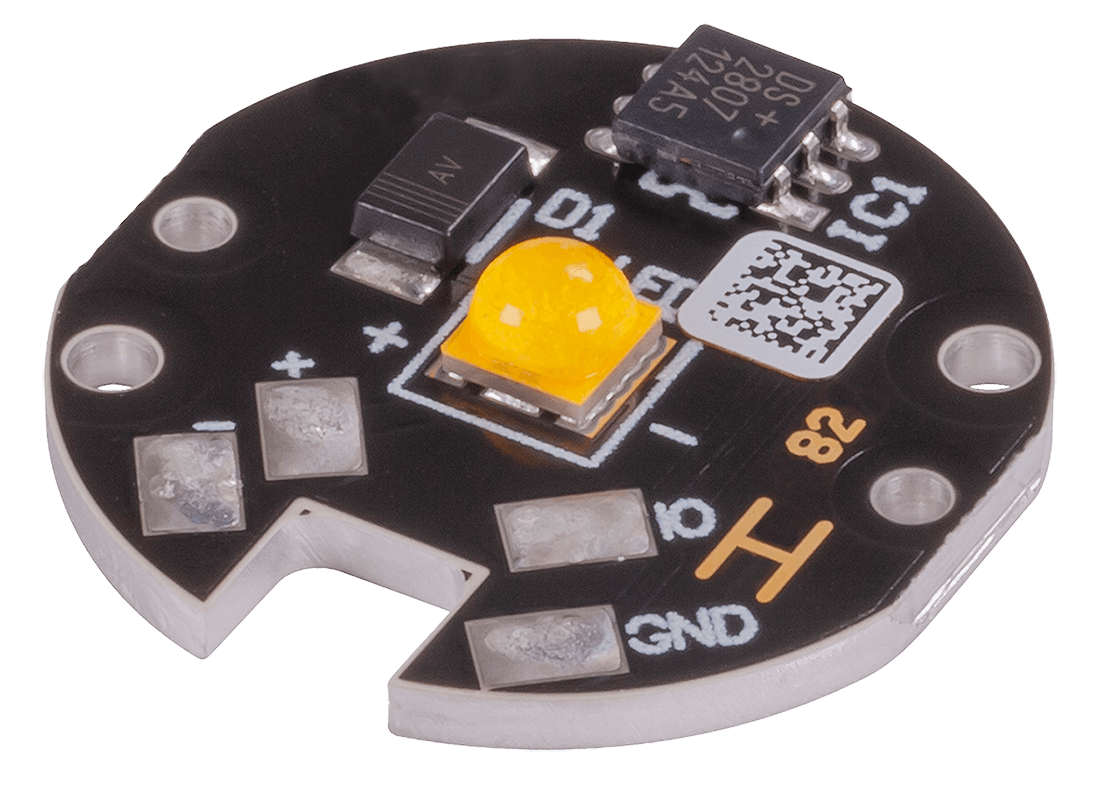

The metal core printed circuit board comprises a thermal insulating layer, a metal plate, and metal copper foil. It has high magnetic conductivity, great heat dissipation, high mechanical strength, and outstanding processing performance. There are aluminum, brass, and copper basis materials for metal core base materials. The aluminum substrate is a metal-based copper-wrapped plate with excellent heat transfer and dissipation properties.

A metal core PCB board uses metal as its base material rather than the standard FR4 to spread heat throughout the board. Heat accumulates because of some electronic components operating on the board. The metal aims to direct heat away from essential board components and onto less critical places.